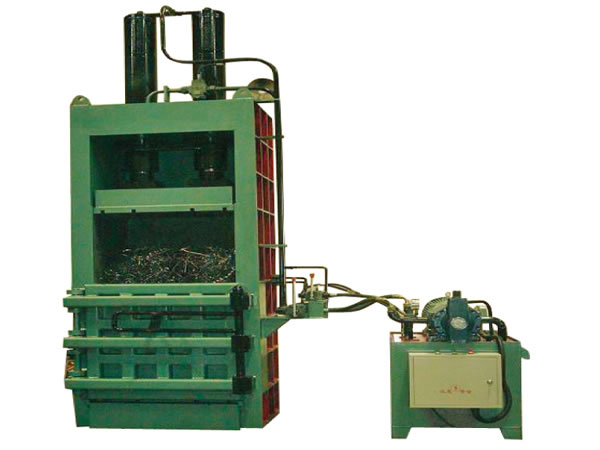

Vertical Scrap Baling Press

This scrap baling press comes in vertical design, thus allowing for small floor space. With standard voltage of 380V, our vertical baler delivers exemplary power output and efficiency. Moreover, the baling machine can be designed with tailor-made operating voltage to meet your specific operating environment.

The same as other styles of metal scrap baler, this vertical scrap baling press is always hunger for waste metal. All you have to do is feed this well conceived metal recycling equipment with your recyclable materials. After main cylinder finishes compressing action, you need to put iron wires into the threading device for bale binding. Then the pusher cylinder pushes bound bale out of the chamber. As you can see, our scrap baling press shows excellence in terms of simple operation and safety.

Advantage

1. Wide application

This vertical scrap baling press has been proved to be perfect to transfer all kinds of soft and thin waste metals such as steel shavings and paint buckets into rectangular bales. These compacted bales with outstanding logistics aspects and superior melting properties making them preferred feed materials.

2. Feeding port

The baling press is designed with a desirable space between the compacting head and the chamber gate, allowing for safe and convenient feeding.

3. Easy binding

The scrap metal compactor employs slot-style press head and chamber bottom, whereby users benefit from easy binding.

4. Salient pusher

On the rear of our vertical scrap baling press is the hydraulic cylinder for pusher. When bales are pressed, this cylinder drives the pusher to transport outgoing materials out of the chamber.

Features

1. The HC81L-1600 vertical scrap baling press has the baling force up to 1600kN.

2. The size of the compression chamber is 1500×800×1500mm. The largest bale size can be 1500×800mm.

3. Our product is installed with two main cylinders.

4. Based on customer demand, the compression chamber size, bale size and the bale shape can be customized.

5. Hydraulic system controlled by manual valve or push button for all machine types.

6. 22kW power, push-out ejecting mode.

English

English Русский

Русский Português

Português